Talent Gaps Impacting Semiconductor Jobs

05 Nov, 20248 minutes

The semiconductor industry is essential for devices that so many of us rely on. However, at present, talent gaps are impacting several key semiconductor jobs. There are several causes, from a lack of graduates to persistent technological developments requiring new skills. The figures are alarming, and if not addressed, they’re forecast to get worse.

Whether it’s a Semiconductor Design Engineer or a Semiconductor Materials Scientist, our guide explores which semiconductor jobs are being impacted by talent gaps.

What’s Causing Talent Gaps?

A shortage of skilled professionals is currently hindering the semiconductor industry - and it’s projected to worsen. It’s estimated that by 2030, globally, there will be a need to add more than one million skilled workers. To meet that demand, semiconductor recruitment must place over 100,000 professionals every year. With numbers of this magnitude, the gap includes several roles, including various engineers and materials scientists.

Here’s an overview of the key contributors to the scarcity of professionals filling semiconductor roles:

- A Lack of Graduates: As semiconductor jobs increase, the number of readily available graduates in STEM fields hasn’t matched the pace. By 2030, it’s forecast that the U.S. will be short of roughly 1.4 million STEM professionals, including scientists and engineers, which will directly impact semiconductor production.

- Aging Workforce: The lack of young graduates is compounded by many workers soon to enter retirement - this has been dubbed a ‘talent cliff.’

- Negative Perception: Many professionals don’t see the appeal of the industry. U.S. semiconductor companies struggle to build a strong brand image compared to other major tech companies, making semiconductor recruitment difficult.

- Shifting Skills: Technological developments have generated a demand for new skills. Today’s professionals must be adept with artificial intelligence and machine learning and understand new materials and their properties.

- Global Demand: America is determined to boost domestic semiconductor production. To achieve this, Donald Trump has suggested imposing tariffs of up to 50% on semiconductor imports. However, the localization of the semiconductor manufacturing process, combined with global competition, has meant companies are often vying for the same small pool of existing talent.

As we know, the shortage of STEM professionals directly impedes the semiconductor industry. The Semiconductor Industry Association (SIA) conducted a study that found the U.S. faces a forecasted shortfall of 67,000 professionals in the semiconductor industry by 2030. But which semiconductor jobs are impacted the most?

Semiconductor Design Engineers

Semiconductor Design Engineers are in short supply, and if the causes of talent gaps aren’t tackled, in just a matter of years, the U.S. could be short of 23,000 designers. To avoid reaching this figure, the specific areas which are lacking must be scrutinized and addressed accordingly. We’ll explore them in detail below:

A Lack of Skills in Digital and Analog Design

Digital and analog design are essential elements of semiconductor production. However, chip development is being stalled by a shortage of specialized skills in digital and analog design.

Digital Design

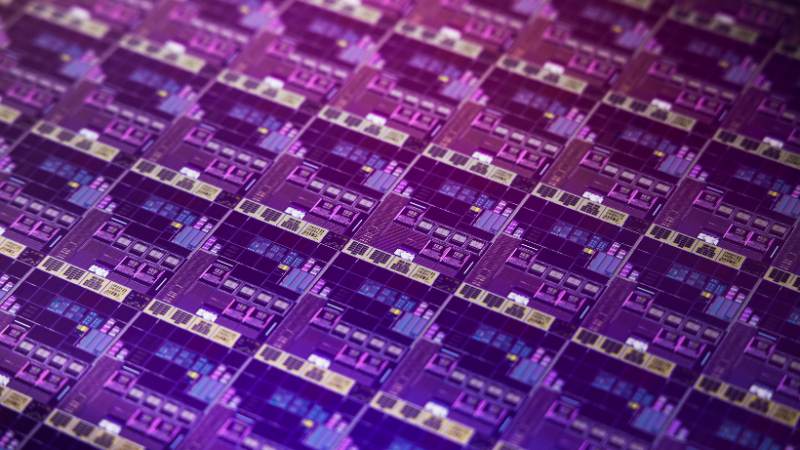

Building intricate digital systems like processors, GPUs, and AI accelerators is a key focus for Semiconductor Design Engineers. This challenging task is compounded by the following issues:

- Complexity of Designs: Contemporary systems-on-chip (SoCs) integrate processing, connectivity, and memory. This means expertise is needed in several areas - including low-power design and high-speed interfaces. Familiarity with advanced node technologies is essential and requires knowledge of FinFET, power optimization, and the challenges of parasitic effects.

- Verification and Validation Knowledge: Much of the semiconductor chip design lifecycle is taken up by verification, meaning confidence in formal verification, simulation, and emulation tools is imperative. Furthermore, there’s a distinct shortage of Semiconductor Design Engineers equipped with SystemVerilog, UVM (Universal Verification Methodology), and hardware-software co-verification.

- Emerging Domains: With AI and ML rising to prominence, demands for custom architectures and accelerators are rising, and so are the skills required for these fields. Additionally, few Semiconductor Design Engineers can utilize hardware description languages like Chisel or HLS tools for domain-specific architectures.

Analog Design

Intuition, experience, and a firm grasp of physics play a key role in analog design. Semiconductor Design Engineers are responsible for building circuits for signal processing, power management, and communication interfaces. Problems encountered include:

- Small Talent Pool: For effective analog design, Semiconductor Design Engineers must understand areas often overlooked in engineering, such as device physics, transistor-level design, and noise analysis. Compared to digital design, there are fewer skilled engineers in this discipline.

- Emerging Applications: Advanced applications like 5G, IoT, and autonomous vehicles depend on analog and mixed signals. However, engineers must know niche expertise covering high-frequency circuit design, RF principles, and precision analog.

- Multi-Disciplinary Challenges: Analog designers have to work closely with digital designers for mixed-signal systems, which means cross-domain knowledge is essential. Equally as important is understanding processes for custom layouts, parasitic extraction, and package integration.

Semiconductor Process Engineers

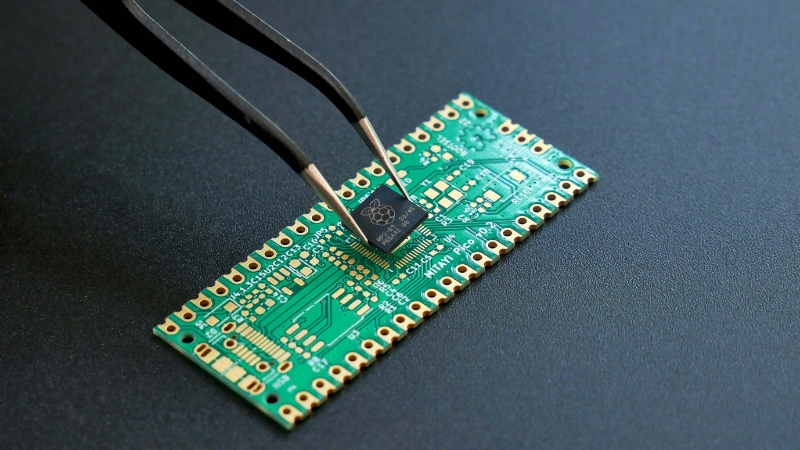

Semiconductor chip design isn’t possible without specialized fabs and engineers with experience in cleanroom protocols and equipment handling. These fabs are being built at a rate the semiconductor industry struggles to cope with. It’s vital that Semiconductor Process Engineers have cleanroom expertise and process engineering skills, including:

- Lithography: This is a critical part of the semiconductor manufacturing process that involves transferring patterns of geometric shapes from a mask to a thin layer of radiation-sensitive material that covers a semiconductor wafer. This is essential for creating the intricate circuitry that’s needed for today’s microelectronic devices.

- Etching: Semiconductor Process Engineers must remove material from a substrate to create the patterns for integrated circuits. The importance of this process is substantiated by the rapid growth of the semiconductor etch equipment market. It has a projected CAGR of 7.60% to reach $34.32 billion by 2029.

- Deposition: This element of the semiconductor manufacturing process adds thin layers of material onto the surface of semiconductor wafers. Over time, the deposition process has changed, meaning that Semiconductor Process Engineers have had to evolve their skills.

- Chemical-Mechanical Planarization (CMP): Semiconductor chips must be smooth and flat. To achieve this, CMP combines chemical and mechanical actions to polish wafers. This ensures that each layer of the chip is flat, which is necessary for the performance and reliability of electronic devices.

The above are advanced manufacturing techniques that demand hands-on experience and training. However, the experienced professionals who could pass on this knowledge are nearing retirement.

Semiconductor Test Engineers

Knowledge of automation and data analysis is essential for improving the efficiency of semiconductor chip design. The need for these skills has been dramatic, and the industry has not been prepared. Most engineers have traditional skills and therefore lack understanding of:

- Automation frameworks like Python, LabVIEW, and TestStand.

- Platforms for big data analytics such as MATLAB and R.

- Statistical process control tools or Six Sigma methodologies.

Testing technologies are becoming increasingly advanced to deal with higher frequencies and bigger data rates. This created the need for engineers to develop skills in:

- RF testing methodologies.

- Optical testing.

- Heterogeneous integration and 3D IC testing.

Recruiting for this semiconductor job is challenging because employers seek professionals who have skills that connect hardware, software, and data science - it’s very rare to find an individual who has experience in all three.

This rarity is worsened by competition for talent from other industries. Automotive and aerospace companies want candidates equipped with automation and data analysis proficiency.

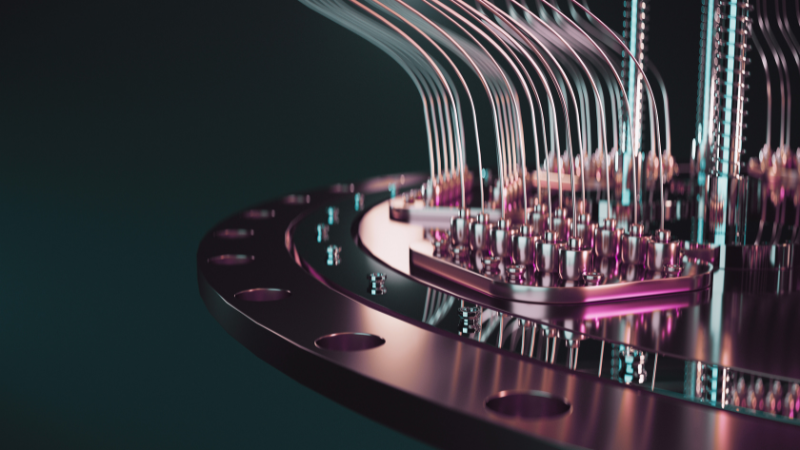

Semiconductor Materials Scientists

A concern for the semiconductor industry is the lack of experts in materials research and development. What’s driving the demand? As discussed, chip designs are increasingly complex and miniature. This requires specialized skills in 3D stacking and quantum computing, which not many professionals have.

Semiconductor materials science requires knowledge of several disciplines, including:

- Physics

- Chemistry

- Materials Engineering

- Electrical Engineering

Because of the demanding nature of this field, it creates difficulty when training professionals.

Limited graduate programs focusing on semiconductor materials science are also a factor, and students tend to prefer other fields, such as software development or data science. Additionally, educational institutions struggle to teach the next generation because technology frequently evolves.

Final Say: Talent Gaps Impacting Semiconductor Jobs

Evidently, there are many reasons for the talent gaps impacting semiconductor jobs. There’s a lack of STEM graduates and an aging workforce, skill requirements that frequently change, and global competition. Combined, these issues have impacted many roles, including Semiconductor Design Engineers, Process Engineers, Test Engineers, and Materials Scientists.

Demand for semiconductor production will accelerate, so addressing these skill gaps needs a clear strategy. Companies could improve their brand image to compete with other tech firms and offer training to continually refresh the knowledge of existing staff. The lack of STEM graduates also needs to be addressed, and this could be done through collaborative efforts between governments, educational institutions, and industry leaders.

Addressing these gaps demands a comprehensive strategy. This includes bolstering STEM education pipelines, enhancing industry branding to attract top talent, and fostering continuous skill development through upskilling and reskilling initiatives. Collaborative efforts between governments, educational institutions, and industry leaders are vital to align workforce development with the evolving demands of semiconductor technology.

Without immediate and sustained action, the talent shortage could hinder innovation and growth in this pivotal industry, affecting global technology ecosystems. Proactively tackling these challenges is crucial to ensuring the semiconductor industry continues to thrive and meet the demands of a rapidly advancing digital age.

Cutting-Edge Semiconductor Recruitment Solutions

At Acceler8 Talent, we are familiar with the difficulties companies face when searching for top-tier professionals to fuel their visionary projects. It takes time, it can be stressful, and it can distract you from leading your business to success. Thankfully, we pride ourselves on discovering the finest talent in the semiconductor industry.

Learn how we can support you. Visit our dedicated semiconductor page or contact us today to connect with a team member.