Challenges Facing Semiconductor Jobs and The Industry in 2025

10 Dec, 20249 minutes

Various challenges threaten semiconductor jobs and the industry in 2025. From a lack of raw materials disrupting supply chains, international friction, technological barriers, a skills gap, and a need to be sustainable, 2025 could have many hurdles for U.S. semiconductor companies. However, when there are challenges, there are growth opportunities.

Our guide explores what could stall the semiconductor industry’s development and discusses the points of promise despite adversities.

Supply Chain Disruptions and Geopolitical Tensions

A combination of supply chain issues and rising geopolitical tensions, particularly between the United States and China, will be challenging for semiconductor jobs in 2025.

Supply Chain Disruptions

Shortage of Raw Materials

Numerous disruptions to supply chains have impacted the global semiconductor industry. Be it a shortage of raw materials or logistical implications, supply chain disruptions are an issue for semiconductor production now and in the future. Several materials that are critical components for semiconductor devices are in short supply for an array of reasons. Here are some examples:

- Neon Gas Shortage: Around 45%-50% of the world’s supply of neon gas is produced by Ukraine. It’s vital for the etching process in semiconductor fabrication. However, due to ongoing conflict, neon gas availability is limited.

- Supply Concentration: Semiconductor manufacturing processes require tantalum and silicon. However, roughly 70% of these materials are supplied by Africa and China.

- Insufficient Water: In 2023, Taiwan droughts impacted the supply of ultra-pure water needed for cleaning silicon wafers. To prevent a recurrence, Taiwan Semiconductor Manufacturing Company (TSMC) established its own water recycling facilities. This transition reduced Taiwanese chip factories’ water usage by 10%-15%.

Logistical Obstructions

Compounding the already short supply of essential raw materials is the slow and delayed transportation of said materials. Port congestion is a particularly problematic contributor, especially at major global shipping hubs. Concerning suppliers, the semiconductor industry depends on a complex network across multiple regions, rendering coordination and deliveries difficult. Also, the quality of shipments can be impeded by temperature and humidity when semiconductor chips are in transit.

Semiconductor manufacturing capacity is also a factor that’s adding to supply chain disruptions. Semiconductor fabs operating at full capacity are still unable to satisfy the demand for chips, with it taking them up to six months or longer to create products.

Geopolitical Tensions

Escalations Between America and China

The United States is eager to become the force it once was in the semiconductor industry. Achieving this means rivaling China, which is something that former and incoming President Donald Trump isn’t shying away from. Trump has proposed a series of stringent tariffs on imports, including:

- A significant 60% tariff on Chinese products.

- A 20% tariff on all imported goods.

There are possible benefits to this, such as the creation of semiconductor jobs in the U.S. However, these tensions have the potential to threaten global semiconductor production.

Tensions in Taiwan

Home to some of the leading semiconductor manufacturers like TSMC, Taiwan is responsible for generating a significant portion of the world’s semiconductor chips. The following numbers demonstrate Taiwan’s presence as a powerhouse:

- Taiwan produces over 60% of the globe’s semiconductors.

- Accounts for 90% of the most advanced chips.

However, as frictions rise, these figures could fall. Trouble in the Taiwan Strait has long been a geopolitical concern. This is an unresolved conflict between the People's Republic of China (PRC) and the Republic of China (ROC, Taiwan) and derives from the end of the Chinese Civil War in 1949.

Hostilities have heightened with the imminent Taiwanese presidential election. The Chinese Communist Party considers Taiwan as part of the People's Republic of China and is pushing for ‘reunification.’

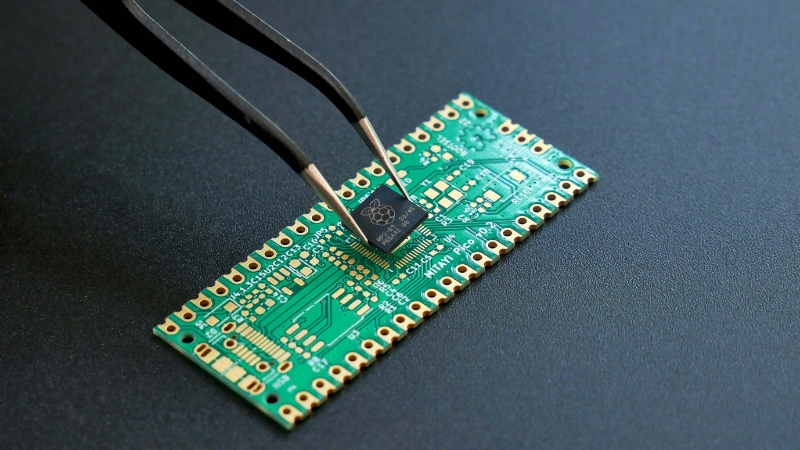

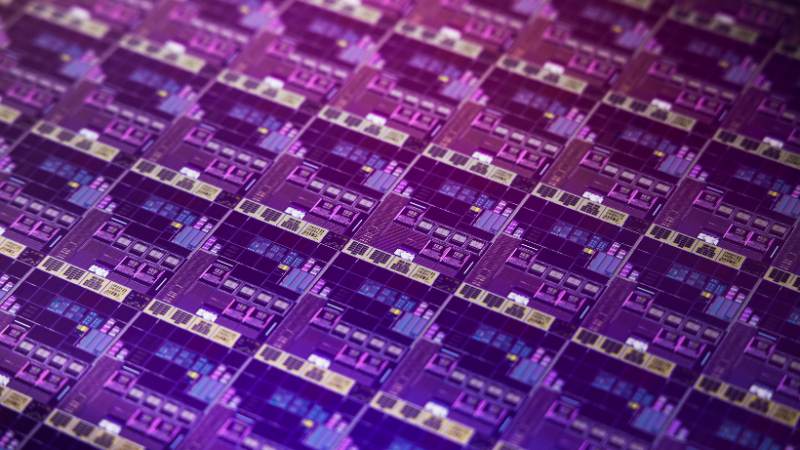

Moore’s Law and Technological Limitations

In 1965, Gordon Moore, co-founder of Intel, predicted that the number of transistors on a chip would double yearly. A decade later, he revised this to every two years. This observation has held true for many years, but experts have reservations about whether this trend will continue. This is primarily due to miniaturization and the associated physical limitations and costs.

Impact on the Semiconductor Industry

Demand for more powerful yet smaller semiconductor chips is not slowing down. However, conversely, there’s a concern that technological developments are.

- Dwindling Progress: Since around 2010, semiconductor advancement has fallen below the pace predicted by Moore’s Law.

- Increasing Costs: The cost of semiconductor fabs is on the rise. This is causing difficulty for U.S. semiconductor companies in investing in the latest technologies.

- Specialized Chips: General-purpose processors are approaching their physical limits. There’s now a shift to creating specialized chips for applications like AI and IoT.

- Economic Implications: Innovation could slow down along with Moore’s Law and affect further digital evolution and economic growth.

A Global Skills Shortage

Globally, the industry struggles with a talent shortage and skills gap that could limit semiconductor chip development. It’s forecast that by 2030, there will be a need for over one million additional skilled workers worldwide.

Difficulties with Semiconductor Recruitment

Attracting and retaining experienced and skilled workers isn’t just an issue for U.S. semiconductor companies; it’s a problem prevalent across the globe. Here’s why:

- Intense Competition: Many sectors are vying for the services of professionals equipped with the skills needed in semiconductor jobs. Software development, data analytics, and consulting companies can entice prospective employees with better packages.

- Location Problems: Many semiconductor manufacturing and research facilities are set up in specific hubs, such as Silicon Valley and Taiwan. Professionals could be unwilling to relocate due to the cost of living. Furthermore, unlike software development, U.S. semiconductor companies can seldom offer remote or hybrid working.

Specialized Skills in Emerging Technologies

Technology is evolving at an unprecedented pace - as illustrated by Moore’s Law. This has driven a demand for particular skills that can be niche and is halting semiconductor production. Below are some key areas:

- Advanced Manufacturing Techniques: Technologies such as Extreme Ultraviolet (EUV) lithography and smaller nodes need proficiency in high-level disciplines like nanotechnology, material science, and equipment operation. As automation and robotics are implemented to streamline semiconductor manufacturing processes, skills in mechatronics, programming, and process optimization are required.

- Artificial Intelligence and Machine Learning (AI and ML): AI and ML are transforming chip design and semiconductor manufacturing processes. Skills adept in algorithm development, computational modelling, and predictive analytics are needed to improve the quality of chips (as we know, chips are being made specifically for AI applications) and increase yields.

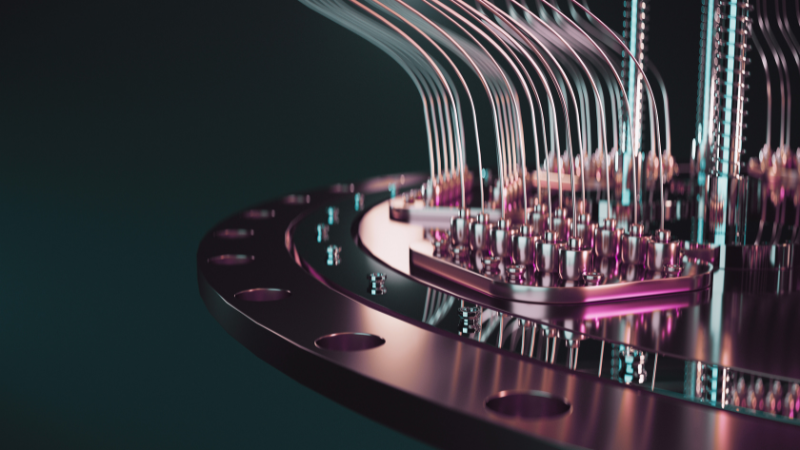

- Quantum Computing: This is a substantial development in computational technology. By utilizing the principles of quantum mechanics, unparalleled computing power can be achieved. Semiconductors play a key role. They’re needed to create several types of qubits, and quantum processors are built on semiconductor chips.

Environmental Sustainability and Energy Efficiency

Sustainability and energy efficiency are shaping semiconductor jobs and the industry as a whole. There’s increased pressure for U.S. semiconductor companies to demonstrate forward-thinking practices and implement green measures.

Becoming Sustainable

Environmental, Social, and Governance (ESG) is a framework for better understanding a company’s environmental impact. This approach encompasses factors that encourage improved outcomes for society.

The Three Pillars of ESG

- Environmental: This element focuses on a company’s impact on the natural world. This includes reducing carbon emissions, biodiversity conservation, and waste management.

- Social: This aspect concerns an organization’s relationship with its stakeholders, including human rights, supply chain management, and diversity and inclusion.

- Governance: Governance scrutinizes a company’s decision-making processes. Examples are shareholder rights and ethical business practices.

Signifying ESG’s influence, investment in ESG practices is projected to reach $33.9 trillion by 2026. Tech giants are already making changes and trying to overcome these challenges:

- NVIDIA: Used renewable energy for 76% of its global production in 2023-2024.

- Intel: Has ambitions to use 100% renewable energy for its global operations by 2030.

Elevating Energy Efficiency

U.S. semiconductor companies are deploying various strategies to become more energy efficient. Here’s an overview:

Process Innovations

- Smaller Process Nodes: Process technology has enabled chips to become more energy-efficient. For example, shifting to smaller process nodes decreases power consumption per transistor, leading to higher-performing semiconductor chips.

- High-k Metal Gate Technology: This tech is a significant advancement in semiconductor fabrication, especially CMOS devices. It reduces leakage currents in transistors, enhancing power efficiency.

- Advanced Packaging Techniques: Chiplet design and 3D stacking optimize energy usage. This is achieved by shortening interconnects, boosting performance-per-watt.

Semiconductor Manufacturing Processes

- Optimizing Clean Rooms: Clean rooms require energy for air filtration. To combat this, semiconductor fabs are incorporating HVAC systems and AI to reduce energy consumption. These systems use advanced filtration techniques capable of removing 99.999% of particles larger than 0.12 microns.

- Water Recycling: As discussed, chip manufacturing requires vast volumes of water. Many companies are incorporating advanced water recycling systems to reduce their environmental impact.

Low-Power Chips

- AI and IoT Chips: Companies are designing low-power chips specifically for edge devices. This reduces the need for power-consuming data processing.

- Voltage Scaling: This technique is utilized to decrease power consumption while optimizing performance in integrated circuits. Examples include Dynamic Voltage Scaling (DVS), Adaptive Voltage Scaling (AVS), and Dynamic Voltage and Frequency Scaling (DVFS).

- Energy Harvesting Semiconductor Chips: This emerging technology aims to transform ordinarily wasted heat into usable electrical energy. European researchers have made strides with this challenge by developing a new semiconductor material (germanium-tin alloy) for on-chip energy harvesting.

Final Say: Challenges Facing Semiconductor Jobs in 2025

Many challenges face semiconductor jobs and the industry in 2025. Whether it’s disruptions to supply chains, geopolitical tensions, or workforce shortages, the industry must find ways to be flexible and resilient. There are indications that the semiconductor industry can handle these challenges.

For example, investments in advanced manufacturing and sustainable technologies show a willingness to overcome obstacles. Companies like NVIDIA and Intel have proven that ESG goals can be met without sacrificing productivity. Furthermore, the move to specialized chips that use ambient energy sources, coupled with cutting-edge tech like quantum computing, highlights the capabilities of semiconductor development.

Collaboration across governments and academic institutions will be needed to address the skills gap. Also, U.S. semiconductor companies must build a strong brand image to challenge negative perceptions of having a semiconductor job. It’s also pivotal that supply chains are strengthened and strained international relationships are dealt with delicately.

Relentlessly Pursuing Cutting-Edge Semiconductor Talent

Don’t let your company’s progress be stalled by challenges that could affect the semiconductor industry in 2025. At Acceler8 Talent, our consultants are passionate about the industry and have an extensive network. Our semiconductor recruitment solutions will help you discover the finest talent so your business can shape the future.

Visit our dedicated semiconductor page or contact us today to connect with a member of our team.